In the precision-driven age we live in, kalibraatio – the Finnish term for calibration – is a hidden hero behind countless operations. From healthcare devices to aerospace engineering, from your kitchen scale to complex AI systems, calibration ensures that the numbers we rely on truly mean what we think they do.

But what exactly is kalibraatio? Why is it crucial, and how does it impact industries, safety, science, and even our everyday lives?

This article explores the concept in depth, breaking it down from a practical, technical, and future-oriented perspective. Whether you’re an engineer, technician, or a curious reader, by the end you’ll understand why kalibraatio matters more than most people realize.

What Is Kalibraatio?

Kalibraatio refers to the process of comparing the measurement values of an instrument to a known standard. It’s not about fixing a device but evaluating how accurate (or inaccurate) it is. The outcome typically includes documentation that outlines any deviation from the standard and, when necessary, correction values to ensure measurement precision.

In simpler terms, imagine you’re weighing flour for baking. You trust the scale to show you the correct weight. But what if that scale was off by 10 grams? Calibration would catch that discrepancy, helping you get the right results.

Why Kalibraatio Is Essential

Accuracy is critical. Whether it’s a lab testing blood samples or a manufacturer ensuring engine components meet strict tolerances, mismeasurements can lead to failure, danger, or loss.

Examples of real-world impacts of poor calibration:

- In aviation, a miscalibrated pressure sensor could lead to catastrophic altitude misreadings.

- In medicine, a wrongly calibrated thermometer could give misleading temperature readings, resulting in incorrect treatment.

- In energy production, misreadings from flow meters can affect billing, performance, and compliance.

Across industries, kalibraatio builds the foundation for reliability, trust, and safety.

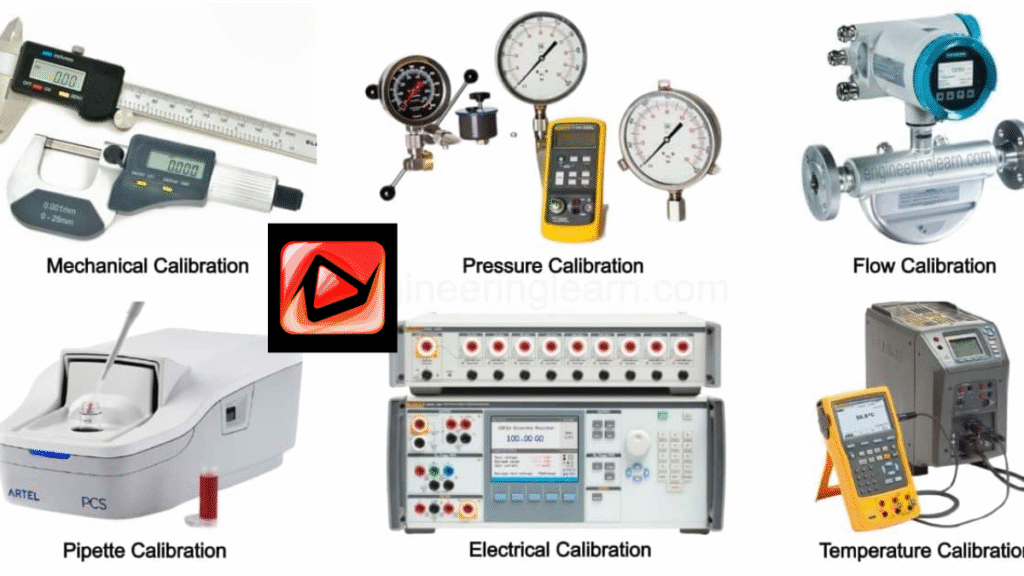

Types of Kalibraatio Processes

Calibration is not one-size-fits-all. It varies depending on the equipment, required precision, and the nature of what’s being measured.

Dimensional Calibration

Used for tools measuring length, thickness, diameter, or any geometric property. Think micrometers, calipers, rulers, and coordinate measuring machines.

Mechanical Calibration

Applied to scales, weights, pressure gauges, and torque wrenches. For example, vehicle repair centers rely heavily on torque calibration for safety.

Electrical Calibration

For multimeters, oscilloscopes, power meters – any instrument dealing with voltage, current, or resistance.

Thermal Calibration

Used in devices like thermometers, furnaces, and freezers. In food, pharma, and healthcare, thermal calibration is often legally mandated.

Chemical Calibration

Common in laboratories, especially with pH meters, titration systems, and spectrophotometers.

Key Steps in a Standard Kalibraatio Procedure

Here’s what a typical calibration process looks like:

- Requirement analysis – Determine the purpose and acceptable tolerance for measurements.

- Reference selection – Use a known, traceable standard with higher accuracy than the device being calibrated.

- Measurement comparison – The device is tested against the standard across a range of values.

- Deviation analysis – Calculate the difference between expected and actual readings.

- Adjustment (if needed) – The device may be recalibrated or marked with correction factors.

- Documentation – Results are recorded in a calibration certificate.

- Scheduling next calibration – Set a date based on usage frequency, criticality, and environment.

Kalibraatio in Different Industries

Healthcare

Medical tools like blood pressure monitors, defibrillators, and infusion pumps need precise calibration to protect patient safety and comply with regulatory frameworks (like ISO 13485).

Automotive and Aerospace

Every bolt’s torque, every angle of a wing, and every component’s size must be perfect. Kalibraatio ensures that complex machinery functions exactly as intended.

Food & Beverage

Temperature sensors in ovens, refrigerators, and pasteurizers must be accurate to guarantee safety and product consistency.

Manufacturing and Robotics

High-speed production lines rely on sensors and actuators – all of which need calibration to ensure repeatability, accuracy, and productivity.

Environmental Science

Instruments used to measure air, water, and soil quality – such as gas analyzers and spectrophotometers – depend on precise calibration for trustworthy data.

The Power of the Calibration Certificate

A calibration certificate is more than a piece of paper – it’s an accountability record. It provides transparency and traceability, often listing:

- Device identification

- Date and location of calibration

- Reference standards used

- Observed values and deviations

- Measurement uncertainty

- Calibration technician’s signature

Companies storing certificates properly benefit during audits, certifications, or legal evaluations.

When Should You Calibrate?

Calibration intervals depend on several factors:

- Manufacturer’s recommendation

- Legal or industry regulations

- Criticality of measurement

- Environmental conditions

- Frequency of use

Best practices suggest:

- Before first use

- At regular scheduled intervals (e.g., annually)

- After repairs or suspected damage

- Following major changes in environmental conditions

- If readings seem inconsistent

Automated and Smart Kalibraatio: The Future Is Here

With the rise of Industry 4.0, kalibraatio is evolving rapidly.

Emerging trends include:

- Self-calibrating sensors – These devices can verify and adjust themselves autonomously.

- Remote calibration systems – IoT-enabled devices that trigger calibrations based on conditions or usage.

- AI-powered analytics – Predict when a device is drifting out of tolerance.

- Blockchain verification – For secure and transparent calibration records.

This makes calibration more predictive than reactive – reducing costs, downtime, and risk.

Standards & Quality Systems That Rely on Kalibraatio

Calibration isn’t just good practice; it’s a core requirement of many quality frameworks:

- ISO 9001 – Demands traceability and documented evidence of instrument accuracy.

- ISO/IEC 17025 – Applies specifically to testing and calibration labs, emphasizing competence and technical validity.

- GMP (Good Manufacturing Practices) – In pharmaceutical and food sectors, mandates calibration of all critical instruments.

Failing to meet calibration requirements can result in fines, product recalls, or revocation of certification.

Common Misconceptions About Kalibraatio

Let’s debunk a few myths:

- “New equipment doesn’t need calibration.”

False. Even brand-new devices can be off-spec due to shipping damage or manufacturing variances. - “Calibration is just a formality.”

Absolutely not. Calibration can be the difference between safe operation and dangerous failure. - “We can use correction factors instead of recalibrating.”

Correction factors help short-term, but without rechecking against a standard, there’s no guarantee of accuracy.

Real-World Case: Kalibraatio Saving Millions

A manufacturing firm in Finland was experiencing quality issues on their production line. After weeks of investigation, they discovered that a single miscalibrated laser sensor had been causing parts to be cut 0.5 mm too short. Over 30,000 parts were rejected – costing hundreds of thousands in materials and labor.

After introducing regular kalibraatio checks, scrap was reduced by over 90%, and customer satisfaction soared.

Summary: Kalibraatio Is Precision’s Silent Guardian

Whether you’re dealing with microns or megawatts, kalibraatio plays a crucial role in ensuring everything runs as it should. It guarantees the credibility of measurements, the safety of processes, and the quality of products.

And while the concept may seem purely technical, its implications touch lives every day. The smartphone in your hand, the car you drive, and the medications you take all rely on the quiet precision that kalibraatio delivers.

In a world that’s only becoming more digitized and interconnected, calibration is evolving too – becoming smarter, faster, and more autonomous. But its fundamental purpose remains unchanged: helping us trust the numbers we depend on.

For more information visite the website